Near-Net Shape Manufacturing of Miniature Spur Gears by Wire Spark Erosion Machining

ebook ∣ Materials Forming, Machining and Tribology

By Kapil Gupta

Sign up to save your library

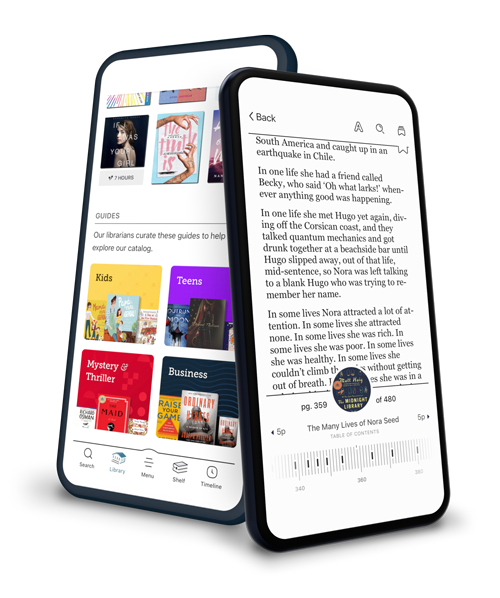

With an OverDrive account, you can save your favorite libraries for at-a-glance information about availability. Find out more about OverDrive accounts.

Find this title in Libby, the library reading app by OverDrive.

Search for a digital library with this title

Title found at these libraries:

| Library Name | Distance |

|---|---|

| Loading... |

This work describes an experimental investigation with the aim to evaluate and establish wire spark erosion machining (WSEM) as a viable alternative for high quality miniature gear manufacturing. External spur type miniature brass (ASTM 858) gears with 12 teeth, 9.8 mm outside diameter and 5 mm face width were manufactured by WSEM. The research work was accomplished in four distinct experimental stages viz., preliminary, pilot, main and confirmation. The aim, scope and findings of each stage are progressively presented and discussed. In essence, the investigation found that it was possible to manufacture miniature gears to high quality by using WSEM. Gears up to DIN 5 quality with a good surface finish (1.2 μm average roughness) and satisfactory surface integrity were achieved. The results suggest that WSEM should be considered a viable alternative to conventional miniature gear manufacturing techniques and that in some instances it may even be superior. This work will prove useful toresearchers and professionals in the field of miniature and micro-scale manufacturing and machining.