Towards a Renewable Future

ebook ∣ Assessing Resource Recovery as a Viable Treatment Alternative: Case Studies of Facilities Employing Extractive Nutrient Recovery Technologies · WERF Research Report

By Ronald Latimer

Sign up to save your library

With an OverDrive account, you can save your favorite libraries for at-a-glance information about availability. Find out more about OverDrive accounts.

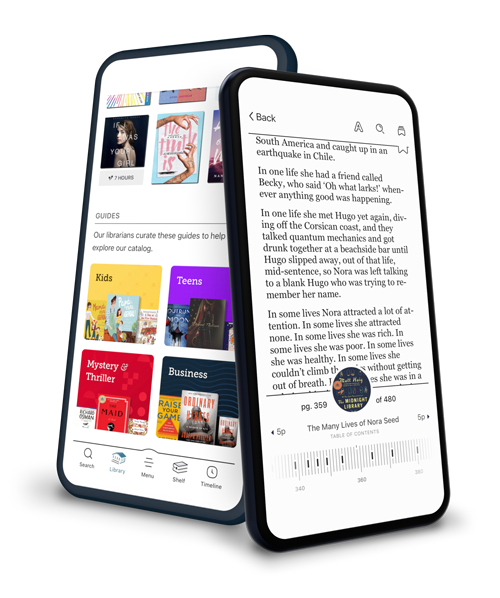

Find this title in Libby, the library reading app by OverDrive.

Search for a digital library with this title

Title found at these libraries:

| Library Name | Distance |

|---|---|

| Loading... |

Extractive nutrient recovery, defined as the production of chemical nutrient products devoid of significant organic matter, represents a complementary strategy for managing nutrients in multiple waste streams. In this option, energy and resources are used to accumulate and produce a chemical nutrient product that is recyclable and has a resale value that could potentially help offset operating costs while reducing nutrient production from raw materials for agricultural or other uses. This report (NTRY1R12b) presents a compilation of case studies of water resource recovery facilities (WRRFs) at various stages of implementation of extractive nutrient recovery technologies in the form of struvite crystallization. Of the 20 WRRFs identified in this report, six have implemented or are implementing a struvite crystallization facility and seven have performed desktop and/or pilot evaluations. Data from these thirteen utilities were used to develop the Tool for Evaluating Resource Recovery-Phosphorus (TERRY-Phosphorus), which was used to perform a conceptual level evaluation of implementing struvite recovery at seven other WRRFs.

Data from the full-scale WRRFs that have implemented struvite recovery indicate that sidestream soluble phosphorus removals ranged from 80 to 90%, while ammonia removal ranged from 7 to 30%. Struvite production ranged from 64 to 421 metric tonnes per year and was found to be dependent on the site specific conditions and technology employed. Drivers for implementing nutrient recovery included reduction in supplemental carbon requirements for nitrogen removal, reduction in aeration requirements, reduction in biosolids production versus conventional treatment alternatives, reduction in costs associated with mitigating nuisance precipitate formation, benefits to sludge dewaterability, and benefits associated with manipulating the N and P content of the biosolids. Quantifying the economic and non-economic benefits of these drivers together with site specific factors can help drive the implementation of resource recovery systems at full-scale WRRFs.