Surface Complexation Modelling and Aluminum Mediated Phosphorus--White Paper

ebook ∣ WERF Research Report

By D. Scott Smith

Sign up to save your library

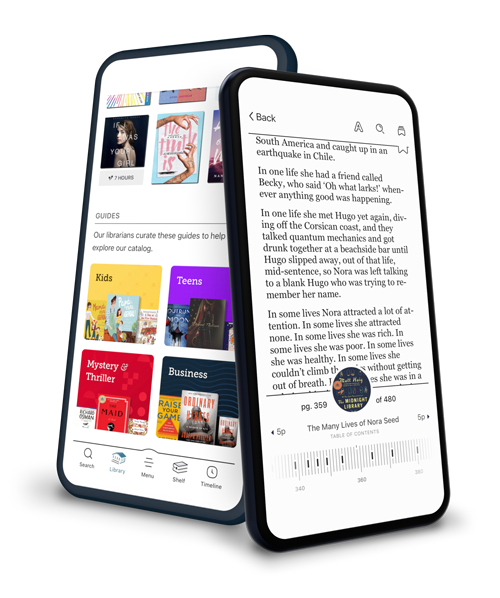

With an OverDrive account, you can save your favorite libraries for at-a-glance information about availability. Find out more about OverDrive accounts.

Find this title in Libby, the library reading app by OverDrive.

Search for a digital library with this title

Title found at these libraries:

| Library Name | Distance |

|---|---|

| Loading... |

Nutrient removal, specifically phosphorus, is an important objective during wastewater treatment. Chemically mediated phosphorus involves adding metal salts (Al3+, Fe2+, Fe3+) and removing the resultant solid phase via solid liquid separation techniques. The mechanism for phosphorus, and in particular phosphate, to partition into the solid phase is not definitively known for aluminum mediated removal.

Here, the researchers test a conceptual surface complexation modeling framework, originally developed for ferric mediated removal. It is found that the same model framework as describes ferric experiments also works for aluminum experiments. The magnitude of the surface reactions (logK values) are different for the two models, but the same types of surface reaction stoichiometries describe data for phosphate removal batch tests using both cations (ferric and aluminum). Thus, in an equilibrium sense, aluminum and ferric phosphate removal chemistries are similar, but this is not true from a kinetic experiment. In previous ferric experiments, it was found that the surface complexation reaction involved a fast first step (minutes) followed by a slow second step (at least 24 hours for equilibration), but for aluminum the removal of phosphate is essentially instantaneous (on the order of seconds).

Here, the researchers test a conceptual surface complexation modeling framework, originally developed for ferric mediated removal. It is found that the same model framework as describes ferric experiments also works for aluminum experiments. The magnitude of the surface reactions (logK values) are different for the two models, but the same types of surface reaction stoichiometries describe data for phosphate removal batch tests using both cations (ferric and aluminum). Thus, in an equilibrium sense, aluminum and ferric phosphate removal chemistries are similar, but this is not true from a kinetic experiment. In previous ferric experiments, it was found that the surface complexation reaction involved a fast first step (minutes) followed by a slow second step (at least 24 hours for equilibration), but for aluminum the removal of phosphate is essentially instantaneous (on the order of seconds).